Wrought Ironwork Finishes

Our guide to choosing your finish

With most of our products we offer a dark burnished steel (formerly called natural black) finish. Here is a little guide to what these finishes are and how they are achieved - if you have any questions at all, we are here to help - just call us on 01473 487 777 or or email sales@nigeltyas.co.uk.

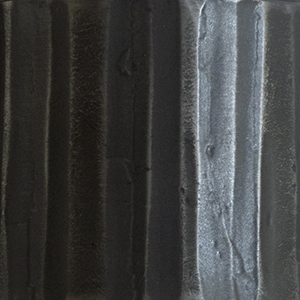

Natural black

Our favourite finish and the most traditional for forged iron and steel. It displays the finest textures of the metalwork.

To achieve this finish, the surface of the metal is heated and oxidised to bring out the subtle colours and shades of hand-forged iron. It is then dipped in hot beeswax. As the wax cools it hardens to give a protective finish and can be left matt or buffed to a soft sheen. This process give a soft, barely black finish with attractive variegated patina of natural hues. Blacksmiths have used beeswax to seal their metalwork for centuries – our own ‘special recipe’ beeswax finish is enhanced only slightly for modern times!

Hand forged details and polished highlights

On some of our ironwork, the 'Illions' range in particular, we like to highlight some of the markings left by the hammer strokes. We buff the textured surfaces to subtly bring out the brighter tones of the underlying metal in the highlights and then coat these items in the clear lacquer, to preserve the contrast of the finish.

Antique Bronze, Brass and Nickel fittings

Some of our lighting products are supplied with ceiling fittings, galleries and/or cord grips in Antique Bronze, Brass or Nickel.

Products available in these finishes are clearly marked.

Antique Bronze - a solid brass fitting with a bronze patina.

Nickel - a solid brass fitting with Nickel plating giving a bright, highly polished surface that is softer than chrome.

[ Pictured left, ceiling rose fittings in Nickel (top left), Antique Bronze (top right) and Brass (front centre). ]

Curtain poles for Tab-top and Eyelet Curtains

Here’s a little advice if you intend to hang tab-top or eyelet style curtains direct from your poles, without the use of curtain rings or hooks.

Our natural black curtain poles come with a natural beeswax finish as standard. They are carefully buffed and polished before they leave our workshop but, because the beeswax is a natural product, there is still a small possibility that there could be a slight transfer of wax onto fabrics in direct contact with the pole. So, for light-coloured tab-top, eyelet or slotted curtains, you may prefer to have your curtain poles painted matt black which we can arrange for you.

Please let us know your preference when you place your order.

Care instructions for our metalwork

All of our ironwork products will benefit from the occasional application of a good quality wax furniture polish. This will keep the lustre of the surface metal looking good. We want you to feel confident about placing your order so, if you have any queries at all, we are here to help - just call us on 01473 487 777 or or emailsales@nigeltyas.co.uk with any questions.